The DTF Shaker is an innovative tool that transforms custom tee creation by seamlessly integrating with curing and heat press processes, ensuring precise, high-quality results for intricate designs and large productions. Compatible with DTF transfer sheets, it streamlines production, saves time, and minimizes errors, making it a vital asset for businesses in the DTF Shaker-driven custom apparel market.

“Revolutionize your printing process with the DTF Shaker—a game-changer in the industry. This innovative tool seamlessly integrates with existing curing and heat press systems, offering unparalleled efficiency and product quality.

In this article, we’ll explore the DTF Shaker’s functionality and its impact on streamlining operations. From understanding its unique features to examining its compatibility with curing processes and heat presses, we’ll delve into how this technology is transforming the way you create high-quality products.”

- Understanding DTF Shaker and Its Functionality

- Integration with Curing Processes: Streamlining Efficiency

- Heat Press Compatibility: Maximizing Product Quality and Speed

Understanding DTF Shaker and Its Functionality

The DTF Shaker is a revolutionary tool that seamlessly integrates with curing and heat press processes, transforming the way custom graphic tees and other products are created. Its primary function lies in its ability to shake and distribute custom dtf transfers evenly onto various materials, ensuring precise application. This innovative technology is particularly beneficial for businesses dealing with dtf transfer sheets, as it streamlines production, enhances quality, and saves time.

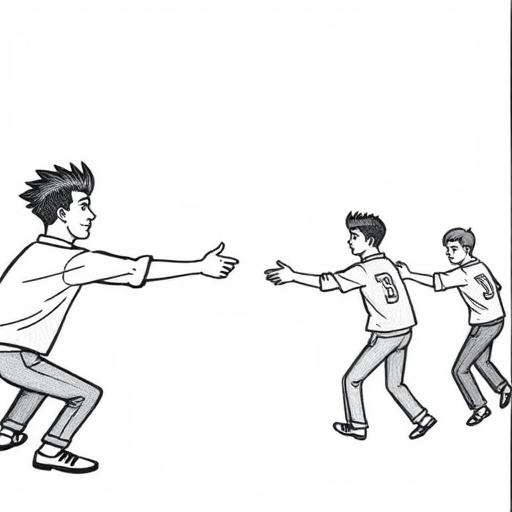

With a simple shaking motion, the DTF Shaker applies pressure and movement to the transfer sheet, allowing the design to perfectly align itself on the substrate. This hands-free approach eliminates potential human error and ensures consistent results. Whether you’re working with intricate designs or large-scale productions, this shaker works tirelessly to deliver flawless custom dtf transfers, making it a game-changer for those in the custom apparel industry.

Integration with Curing Processes: Streamlining Efficiency

The DTF Shaker integrates seamlessly with curing processes, streamlining efficiency and enhancing productivity in apparel production. By utilizing this innovative technology, manufacturers can achieve precise control over the transfer process, ensuring consistent quality and speed. The DTF Shaker’s compatibility with heat press machines allows for a streamlined workflow, where printing and curing occur in tandem, minimizing downtime and maximizing output.

This integration optimizes the entire DTG (Direct-to-Garment) printing for t-shirts process, from design to final product. With the DTF transfer method, intricate designs can be applied with ease, making it an excellent solution for custom apparel and small batch production. The result is a more efficient, cost-effective, and versatile system, catering to the dynamic demands of modern fashion industries, where DTG printing for apparel has become a game-changer.

Heat Press Compatibility: Maximizing Product Quality and Speed

The DTF Shaker’s seamless integration with curing and heat press systems elevates the quality and speed of your product creation, making it a game-changer for custom apparel printing. This innovative technology ensures that the direct to film (DTF) printing process is not just efficient but also consistently delivers superior results. When combined with a heat press, the DTF Shaker optimizes the transfer of designs onto various materials, including personalized hoodies, enhancing their durability and vibrancy.

This compatibility is particularly beneficial for those focusing on DTF printing for dark fabrics. The system’s ability to precisely control temperature and pressure during the heat press step ensures that intricate designs on darker garments remain crisp and well-defined. By maximizing both product quality and production speed, the DTF Shaker offers a streamlined solution for businesses catering to diverse customer demands in the custom apparel market.

The DTF Shaker is a game-changer in the printing industry, seamlessly integrating with both curing processes and heat presses. By understanding its functionality, we can maximize efficiency and product quality. This innovative tool streamlines production, ensuring faster turnaround times without compromising on results. With its compatibility and versatility, the DTF Shaker works harmoniously to meet the demands of modern manufacturing, leaving folks impressed with its indelible impact.