The DTF Shaker is a revolutionary technology for direct-to-garment (DTG) printing, offering unparalleled precision, efficiency, and versatility. It seamlessly integrates hot and cold peel films to ensure optimal design transfer onto various fabrics, from cotton tees to polyester jackets. With quick turnaround times, high-quality results, and custom gang sheets, it's perfect for small batch productions or on-demand garments. The DTF Shaker allows businesses to adapt their methods according to fabric types and design requirements, catering to food, retail, and promotional sectors by enhancing product packaging, prototypes, and marketing materials, ultimately boosting brand visibility and customer satisfaction.

“Discover the revolutionary power of the DTF Shaker, a game-changer in material handling. This innovative technology seamlessly works with both hot and cold peel films, offering unparalleled versatility. By understanding how DTF Shakers harness dynamic tension film peeling, we uncover their numerous advantages—from enhanced productivity to improved material quality. Explore diverse applications across industries, from packaging to construction, as this tech reshapes workflows and drives success.”

- Understanding DTF Shaker Technology

- Advantages of Using Hot and Cold Peel Films

- Applications and Industries Benefiting from DTF Shaker Innovation

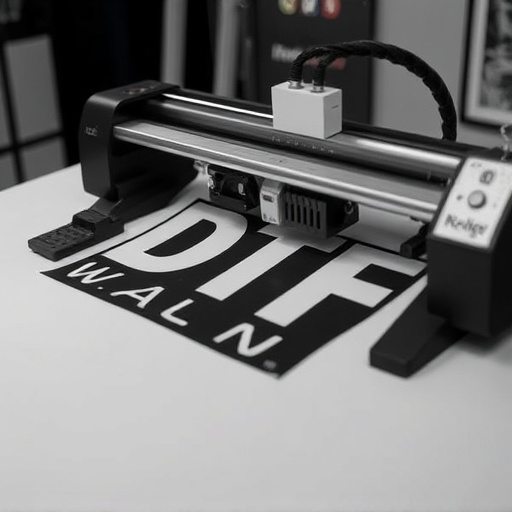

Understanding DTF Shaker Technology

The DTF Shaker is a groundbreaking technology that has revolutionized the world of direct-to-garment (DTG) printing. This innovative system combines precision and efficiency, allowing for both hot and cold peel films in the printing process. By utilizing specialized shakers, the DTF method ensures optimal transfer of designs onto various fabrics, making it a versatile option for custom garment printing. The technology is designed to handle a wide range of materials, from cotton tees to polyester jackets, offering businesses and designers a competitive edge in the apparel industry.

DTF Shaker technology streamlines the production process, enabling quick turnaround times and high-quality results. It is particularly advantageous for small batch productions or creating unique, on-demand garments. With ready-to-press dtf transfers and custom gang sheets, this technology caters to various printing needs. The ability to work with both hot and cold peel films makes it a versatile tool, ensuring that businesses can adapt their printing methods to suit different fabric types and design requirements.

Advantages of Using Hot and Cold Peel Films

Using both hot and cold peel films with the DTF Shaker offers several advantages that enhance its versatility and efficiency in various printing projects. Hot peel films are ideal for applying vibrant, rich colors and intricate designs as they allow for precise control during the heating process, ensuring the ink fuses well with the substrate. This makes them perfect for creating visually stunning dtf transfers ready to press, especially on materials like t-shirts and posters.

On the other hand, cold peel films provide a smoother, more delicate application, making them suitable for detailed, fine-art pieces or light-colored fabrics where precision and minimal heat are required. The ability to switch between these two types of peel films allows printers to achieve exceptional dtf color matching by size, catering to diverse client needs and project requirements.

Applications and Industries Benefiting from DTF Shaker Innovation

The DTF Shaker is a game-changer across various industries, offering unique and versatile applications for both hot and cold peel films. This innovative technology has revolutionized the way businesses approach packaging, branding, and product presentation. From food and beverage to retail and promotional items, the DTF Shaker provides an efficient solution for creating eye-catching designs and custom products.

One of its key advantages is the ability to produce high-quality, detailed prints on a range of materials. With dtf online ordering becoming increasingly popular, businesses can now offer fast turnaround times and personalized products to their customers. Whether it’s applying intricate dtf logo transfers or creating vibrant dtf printing services, this technology ensures consistent and precise results. Industries such as fashion, electronics, and even automotive are leveraging the DTF Shaker to enhance their product packaging, prototypes, and marketing materials, ultimately elevating brand visibility and customer satisfaction.

The DTF Shaker, with its versatility in handling both hot and cold peel films, has transformed the packaging industry. Its innovative technology offers numerous advantages, including enhanced efficiency, reduced waste, and improved product protection. This versatile shaker finds applications across various sectors, revolutionizing how products are packaged and presented to consumers. As the demand for sustainable and efficient solutions grows, the DTF Shaker emerges as a game-changer, ensuring a secure place in the industry’s future landscape.